This is a commonly used manufacturing process that helps in manufacturing the parts for tons of known and unknown purposes.

Development of process control in sheet metal forming.

Flange development and protection die entry line.

Sheet metal forming processes.

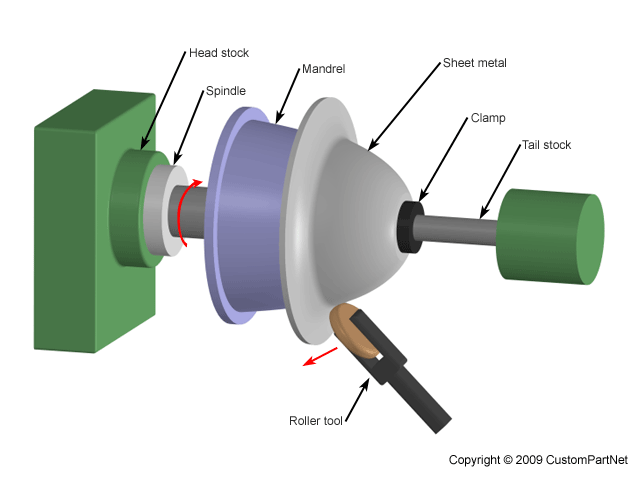

Fig 5 basic elements of isf 5 cnc machine control the tool movement.

Which is forming tool sheet metal blank holder and cnc machine as shown in fig 5.

Sheet metal forming process is done on a press and the parts are formed in between two die.

Problems of part quality in the sheet metal forming process.

Most problems in sheet metal forming come from a bad control of holding restraining and springback.

3 in this strategy a measurable process variable e g punch force is controlled by following a predetermined e g punch force displacement reference trajectory through manipulating the blank holder force.

Blank holder restricts the movement of sheet metal going inward.

Process design is the ensemble of operations leading from the design geometry to.

Development of process control in sheet metal forming.

Read more conference paper.

Joins the punch line to the blankholder with an opening.

By doing so the sheet can be bent or stretched into a variety of complex shapes.

Curling is a forming process that involves de burring sheet metal to produce smooth edges.

Another common sheet metal forming process is bending.

A tool the tool used is hemispherical in design and blank holder is used to clamp the sheet metal.

Schematic of a sheet metal forming process fig.

The sheet metal is placed over a die block at which point a punch presses down.

The applied force stresses the metal beyond its yield strength causing the material to plastically deform but not to fail.

Companies typically perform bending on sheet metal using either a brake press or similar machine press.

A wrinkling b tearing and c springback 1 2 background to overcome production problems tool and die manufacturers continuously integrate new techniques and ideas in sheet metal forming in their design.

One strategy for controlling sheet metal forming processes through the application of variable blank holder force is process control see fig.

The proposed development will be useful in designing and implementing process control in sheet metal forming processes as described in subsequent chapters.